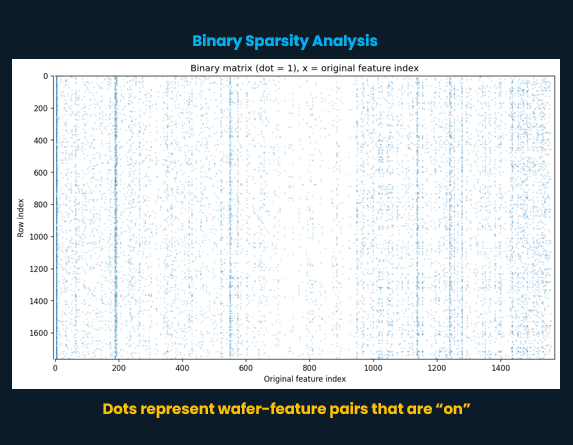

For one of India's largest wafer manufacturers, even small defect rates translate to massive costs. Undetected defects cause downstream failures, warranty claims, and reputation damage, while false alarms waste inspection resources and slow production. Yet defects are rare, buried in sensor data from systems generating 1,500+ sensor readings.

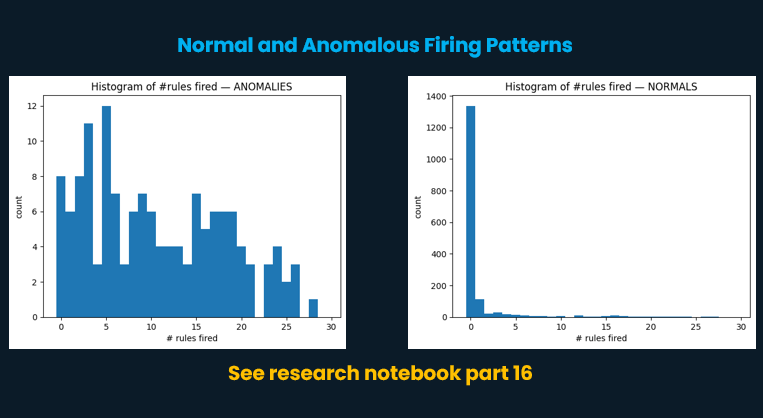

I developed a custom anomaly detection system built from first principles, integrating deep EDA and statistical research, spike-pattern and sensor analysis, and multi-layer rule logic designed to capture the true physical behavior of the machinery.

The resulting model outperforms standard ML baselines – including Random Forest, Logistic Regression, KNN, Hybrid Naïve Bayes, Neural Networks, XGBoost, and LightGBM – in interpretability, stability, and efficiency. This end-to-end approach demonstrates how interpretable models can exceed black-box performance in real industrial environments while delivering over 70% cost reduction through a business-first, insight-driven modeling framework.

Contact me if you'd like to discuss the methodology, business impact, or modeling approach.

quique@databirds.ai

Cost-optimized Wafer Anomaly Detection

Cost-optimized Wafer Anomaly Detection